The transformation of the Valdavia River’s low-lying plains into irrigated land was declared to be of Social Interest in the National Irrigation Plan (Royal Decree 329/2002 of 5 April), based on feasibility studies for the implementation of small irrigation reservoirs carried out at the end of the 1980s.

In 2005, the first of the four Basic Projects for the transformation of the irrigable area of the Valdavia river into irrigation began to be elaborated. In the first of these projects, in 2006, six irrigation sectors were established, coinciding with municipal districts and using direct pumping to the network. A dam was to be built for each of them to divert the water from the Valdavia River, a pumping station with its corresponding pumping assembly and a power line, as well as the subsequent irrigation network.

In addition to this, two reservoirs were planned, one at the source for supplying water in the event of breakdowns or shortages with a 2-day capacity and the other at the end of the line to collect surplus water and regulate the flow of water into the river. In 2008, due to the deregulation of the energy sector and the consequent and the consequent increase in the rates for irrigation, the approach to the project changed.

In 2012, a new basic project was drawn up for the irrigation network, in which a natural pressure irrigation alternative was chosen, to supply two irrigation sectors, coinciding with the land concentration demarcations, covering 1,678 ha the first one and 1,140 ha the second of them, through two collection pipes in two diversion dams of the Valdavia River.

The last of the basic projects, from 2014, includes all the transformation measures, from the dams to the roads. It simplifies the irrigation infrastructure, so that from a single dam, the irrigation network is connected through the same pipeline, which will be supported at peak times by two reservoirs, one at the source and the other in the central part of the irrigation area. The main pipeline designed telescopically, and with a length of more than 40 km, supplies the irrigation branches.

The final design’s advantages include:

- The system is greatly simplified by eliminating the electrical installations and pumping systems.

- From an environmental point of view, this represents the total elimination of power consumption and the resulting CO2 emissions. This fact shows a clear advantage for the immediate future in terms of environmental sustainability.

- Finally, and as a main advantage, this alternative represents an improvement in the irrigators' competitiveness by completely eliminating all power costs. In fact, irrigation could be carried out, in both districts, at no cost in terms of electricity and without having to face the maintenance costs of electrical lines, transformers or pumping stations. Given the ever narrowing profit margins of irrigated crops and the ever-increasing costs of electricity, these savings would be an unparalleled advantage over the other alternatives.

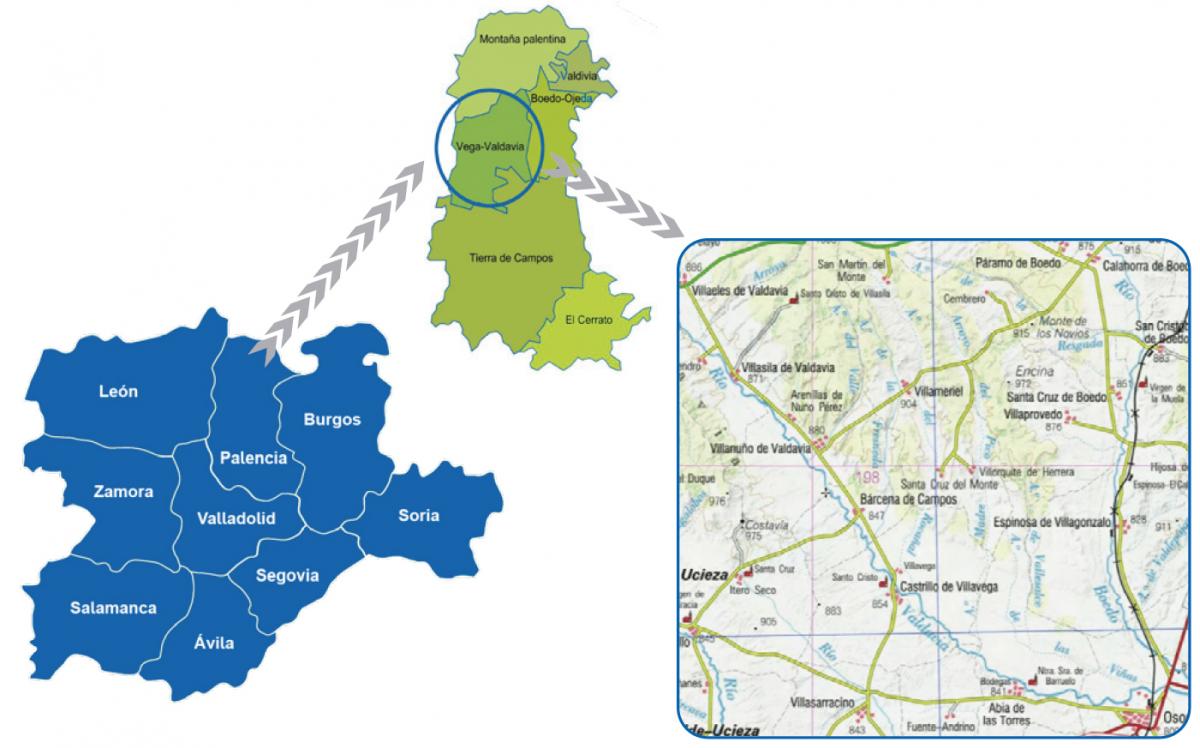

The Irrigation network project for the Valdavia River irrigation area (Palencia) aims to define and quantify the required irrigation works to make use of the water accumulated in the Arroyo Villafría Dam, in the lower Valdavia River valley irrigable area. The objective of the project is to transform 2,700 ha into irrigated land in the municipalities of Villaeles, Villasila de Valdavia, Villanuño de Valdavia, Bárcena de Campos, Castrillo de Villavega and Osorno (Palencia), through a demand-based irrigation system using natural pressure.

The Valdavia Valley is located in the central area of the Palencia province, about 65 km north-east of the provincial capital. To implement the transformation of the irrigable area, six work projects have been drawn up, three of which have been completed and three are underway. Two projects for the two regulation dams on two streams of the Valdavia River, the dam on the Villafría stream (completed) and the dam on the Las Cuevas stream, with a 12 hm3 capacity each of them. Similarly, two rural infrastructure projects were drawn up for the land consolidation road network, which was divided into two districts and which have already been implemented.

Finally, the irrigation infrastructure has been divided into two work projects. The first one contains works of general interest, a reservoir, the construction of two regulation reservoirs and the main pipeline, to bring stored water in the Villafría dam to the irrigation area. The second project with the additional works, from the irrigation network, and that includes the secondary network and the required valves, the tertiary network for supplying the parcels, the automation system, and the remote control to regulate it automatically, and the construction of the Irrigation Community's control center.

Irrigation transformations are one more tool to fight against depopulation and to optimize resources for better crop diversification and production, and consequently greater profitability of the transformed areas.

Using cutting-edge technologies is essential in this type of action to reach maximum energy efficiency for water distribution, which will undoubtedly have an impact on the profit margins of irrigators when it comes to making the investment involved in the transformation profitable.

Th is is where the TOM® Oriented PVC (PVC-O) pipes, come in, given their maximum efficiency in water transport from their greater hydraulic capacity in some cases and their low surface roughness in others. Since power framework has changed, and the cost of contracting power, as well as the proper price per kW/h consumed, is very high, being able to design a system of this magnitude that does not depend on electricity is both very valuable and remarkable. Making the most of the terrain's transformation and its natural slopes to irrigate a 2,700 hectare area, as is the case, has many merits.

Therefore, the purpose of this action is to provide the area with water resources using a demand irrigation system, with natural pressure. This means that no power costs are incurred for pressure irrigation on the plots, which unquestionably makes them very competitive in terms of their operational cost-effectiveness.

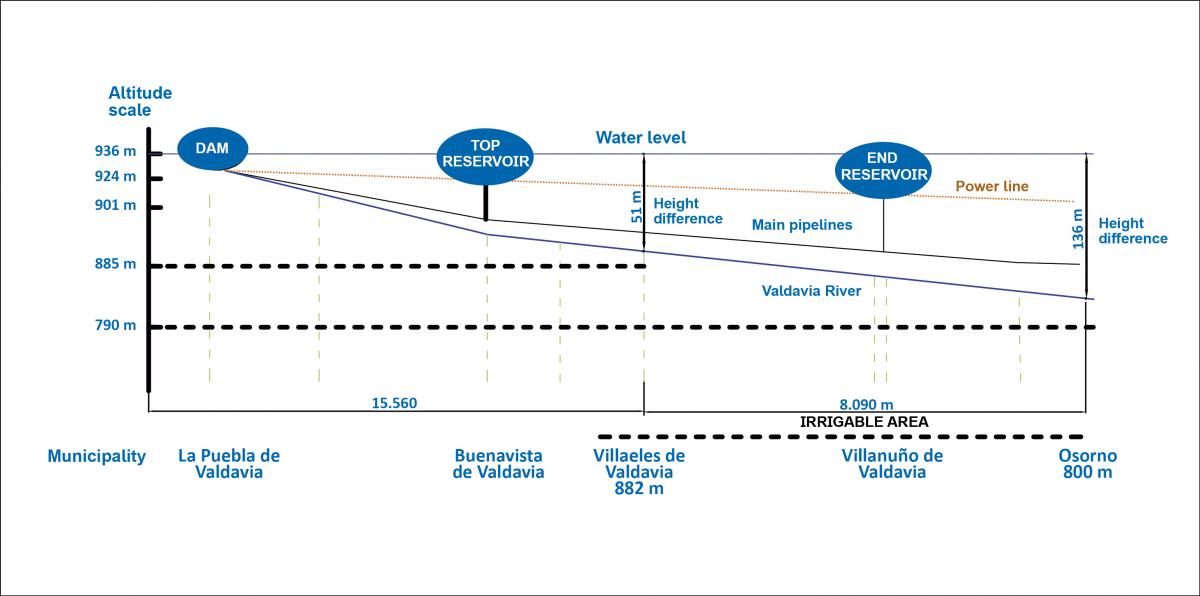

The general scheme for the irrigation infrastructure is as follows, starting with a dam on the Valdavia River, upstream of La Puebla de Valdavia, at an elevation of 936 meters above sea level, and using a 1,000 to 1,200 mm diameter pipe, that is 23,650 meters long, the necessary flow will be transported by gravity to the irrigation network.

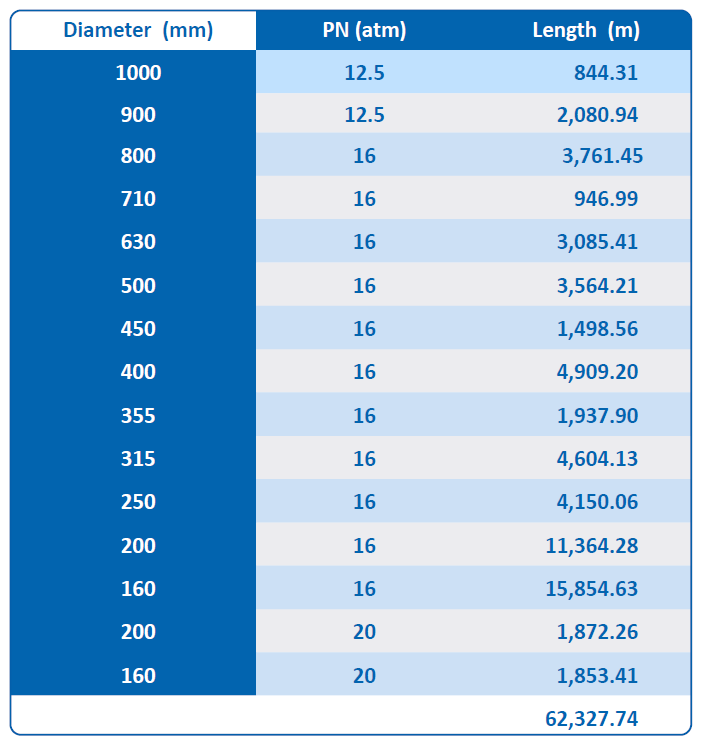

The secondary network has pipes from 160 mm and 1000 mm and a length of 62 km. It is designed in 900 and 1,000 mm diameters, being from the 800 mm diameter in Oriented PVC (PVC-O). It will supply 182 irrigation units, and the tertiary network will come out of the hydrants, with more than 40 km of TOM® PVC-O pipes. Two regulation reservoirs will be built, one before reaching the irrigation area in Arenillas de San Pelayo and the other in Villanuño de Valdavia. These reservoirs will serve to store water during the peak demand periods, to make up for the lack of supply from the dam, and to reduce the diameters used in the main pipeline.

Diversion dam

North of the town of La Puebla de Valdavia, at a height of 936 meters above sea level, a 12 meters wide and 1.20 m high dam has been built in the Valdavia river. The reservoir can hold 12,449.32 m3 of water. Based on the environmental conditions, this is a dismountable structure made of sheet metal panels that, during the irrigation season, it will divert the waters regulated by the headwater dams, with a maximum of 1,400 l/s to the conduction of the infrastructure of the irrigable area.

An intake has been designed on the dam's left bank, which has a 21-meter-long sandbox to ensure that the water entering the pipe is filtered to 2 mm. In a lower pit, before entering the main pipeline, and complying with the immersion levels, the control and communication elements have been installed with the irrigation community's control center.

A continuous fictitious flow was established for the irrigation infrastructure design, that is, the exact flow that would have to be supplied per hectare of land to meet the plants' water needs, if irrigation were continuous for the entire available period (24 hours a day, every day of the month).

Based on July's requirements, as the highest demand month, in which the net alternative needs for irrigation of 69.56% of the area amount to 1,034.5 m3/ha and month, which is equivalent to 0.39 l/s and ha.

Applying the 0.88 application efficiency to these needs, a continuous fictitious flow rate of 0.44 l/s and ha was obtained (0.39 l/s and ha / 0.88). The irrigation demand flow understood as the flow that would need to be supplied per hectare of land being irrigated 6 days a week at 20 hours a day, amounts to 0.62 l/s and ha (0.44 l/s and ha x 168 hours a week/120 hours of irrigation a week), amounts to 1,171.8 l/s, less than the 1,400 l/s maximum flow established in the Irrigation Community's concession.

To provide the network with the established flows and pressures, hydraulic calculations have been made according to the material chosen for the irrigation network pipes, taking into account the hydraulic capacity, execution conditions, maintenance costs and operating quality, and investment cost. The use of steel-reinforced concrete pipe (SRCP) was specified for the main pipeline's largest diameters from the dam, and the beginning of the irrigation network, i.e., from 900 mm to 1,200 mm in diameter.

In the irrigation network, with very high static pressures of between 6 and 15 atm, we have opted to use PVC-O, with 160 mm to 800 mm diameters, and 16 atm stamping. The exception is in the irrigable area’s rear branches, which has been designed with 20 atm nominal pressure pipes. Due to their laminate structure, the TOM® de PVC-O pipes are extremely shock- and crack-resistant and possess excellent mechanical properties.

The reduced wall thickness that occurs in the molecular orientation process yields a larger internal diameter and cross-section of the pipe. In addition, the inner surface is extremely smooth, which minimizes pressure losses and makes it difficult for deposits to form on the pipe walls. Thus, between 15% and 40% more hydraulic capacity is achieved than pipes with similar external diameters made of other materials. In addition to these advantages, there are also those related to its low speed, since the overpressure and underpressure values, as a result of transitory or water hammers caused by sudden variations in the flow supply, are much lower in PVC-O than in the other materials.

The Swamee Jain formula was used to calculate the dam-reservoir pipes, deducting the friction factor “f” from the White Colebrook formula. With a 1,082 l/s flow rate, the pressure in the main pipeline, at the top of the irrigable zone is 44.47 m.c.a, increasing as it moves towards the end of the zone, due to the drop in the topographical level. The continuous fictitious flow would reach the top reservoir at a speed of 2 m/s, with a pressure of 4.74 m.c.a. Thus, it has the capacity to keep up this water flow until full.

In the second case, at a speed of 1.14 m/s, the accumulated load losses are 7.55 m. If the full flow is raised to the top basin at a velocity of 2 m/s, the normal maximum level would be reached at a pressure of 2.95 m.c.a., i.e., it has the capacity to cope with this flow until full. The pipeline of the Top and End reservoirs will be capable of supplying the system with 1,000 l/s and 800 l/s, when the demand is higher than the flow coming from the Dam, either due to an increase in the demand during a top demand week or because it is unused.

The main pipeline is a 23,650 m long telescopic pipe. The first section measures 1,200 mm in diameter and has a 2 and 4.5 atm ringing system, covering a length of 10,792 m. This section will carry the water from the dam to the bypass with the top reservoir.

From the bypass, the connection to the top reservoir will be made with a 1,000 m diameter concrete pipe (SRCP) and 4.5 atm nominal pressure. It is 634 m long. The top reservoir is located in the municipality of Buenavista de Valdavia, in the district of Arenillas de San Pelayo, and can hold 99,859.47 m3 of water. The reservoir's normal maximum level is 924 m, precisely the piezometric level at maximum demand with regards to the Dam.

The main pipeline will continue 2,008 m further, from the bypass to the source reservoir, until reaching the irrigable area, with a 1,100 mm diameter steel-reinforced concrete pipe, with 4.5 and 6.5 ATM rings. The same pipe will be used to build 2,760 more meters in 1,100 mm diameter until reduced to a 1,000 mm diameter. The first irrigation branch line has been designed 11,937 meters from the start of the main pipeline so that it enters at the head of the irrigable area.

Ensuring sufficient natural pressure to irrigate the parcels in this first area, the one located furthest to the north and at the highest elevation, was one of the main conditioning factors when choosing the system and pipeline characteristics. After a diameter reduction from 1,100 to 1,000 mm, which coincides with the road intersection to the north of the Villasila de Valdavia urban zone, it will continue 6,205 meters in the concrete pipe with a 1,000 mm diameter sheet metal jacket and 8.5 and 9.5 atm rings until it reaches the end reservoir bypass.

The bypass pipeline of the top reservoir will be made of PVC-O DN800 mm pipe and 12.5 atm nominal pressure. It is 810 m long. The end reservoir is located in the municipality of Villanuño de Valdavia and can hold 99,813.16 m3 of water. The normal maximum level of the reservoir is 901.5.

From the bypass to the end reservoir, the main pipeline continues until it reaches the road junction located north of the Bárcena de Campos urban zone, with an SRCP DN 1,000 pipe and 12.5 atm nominal pressure, covering 1,885 meters.

A 5 m x 5 m reinforced concrete pit will be placed in the main pipeline's two branches, with a 25 cm thick wall and a tramex to make it traversable. A prefabricated shed measuring 5.4 x 5.4 m outside and 2.50 m in height at the eaves will be installed to cover the pit and house the valve control and connection elements inside. The pit will have a drainage system.

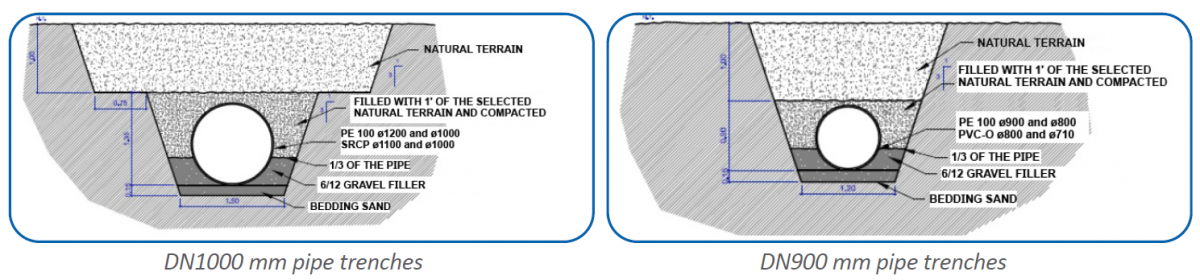

The main pipeline from the Dam to the endpoint is 23,650 m long, with 1,000 to 1,200 mm pipe diameters. The excavation volume for the main pipeline is 197,171 m3, from the ascent to the top reservoir, 4,439 m3, and from the ascent to the end reservoir, 4,610 m3, which means an 8.4 m3/m.l. excavation in the first case, and 7 m3/m.l. and 4.95 m3/m.l. excavation in the two pipelines to the reservoirs.

In all sections, manual leveling of the excavation base will be carried out to ensure that the trench bottom meets the pipe support requirements while obtaining the required lengthwise slopes in each section. The material for the bedding and pipe joint support with 6-30 gravel will be obtained from the first layer sieving of the top reservoir, where the site management, based on the geotechnical study and the necessary tests, will select the collection area. The rest of the chosen material will be transported from the quarry.

The filling will be done with material taken from the excavation itself, compacting it in three layers up to 15 cm above the upper span of the pipe, to cover it with the material straight from the excavation from that point onward. It will be compacted with a compression pan to 98% of the Normal Proctor.

Pipeline tests will be performed using all special parts, valves, hydrants, and vents installed, including manhole covers and anchorage rings with the required strength reached. The test is carried out on the whole installation in this manner. Whenever possible, the test sections will be separated by gate or butterfly valves, to prevent the cap anchor production that causes environmentally harmful concrete residues.

The network's set of auxiliary elements will be installed at the same time as the pipes so that the tests can be carried out jointly. In this way, the assembly guarantees improved performance of the joints, and the parts can be laid with respect to the pipes, avoiding undue stress on them. This is particularly important for valves of more than 1,000 mm in diameter and above to be used.

The irrigation network is made up of 12.5 atm SRCP pipe and PVC-O pipe of 16 and 20 atm working pressure and various diameters. Lengths and diameters are shown in the table below:

The excavation volume for the main pipeline is 188,303.13 m3 from the main irrigation network. The budget includes 1 valve of 800 mm, 2 valves of 700 mm, 1 valve of 600 mm, 3 valves 500 mm, 4 of 400 mm, 3 of 300 mm, 6 of 250 mm, 20 of 200 mm, and 14 of 150 mm.

Trifunctional vents will be placed at the high points of the network and vents downstream when the pipes have high points, to allow the air to escape. Seven 6" valves have been planned, as well as ten 4" valves, 25–3" valves, and 106–2" valves. Drains will be installed at the ends of each branch, when they are low points, and at other low points of the network, located next to rivers or streams. Eighty-one drains have been planned.

Intake hydrants will be installed to collect water needed to irrigate the parcels. Each hydrant will comprise a gate shut-off valve and a stone trap filter will be installed, before the hydraulic valve equipped with a pressure and flow regulator. It ends with a quick connector fitting to the aluminum pipes used in sprinkler irrigation. Remote control will be possible.

Intake hydrants will be installed to collect water needed to irrigate the parcels. Each hydrant will comprise a gate shut-off valve and a stone trap filter will be installed, before the hydraulic valve equipped with a pressure and flow regulator. It ends with a quick connector fitting to the aluminum pipes used in sprinkler irrigation. Remote control will be possible.

For the 2,717 hectares that make up the Irrigation Community, it was distributed in 182 irrigation units, supplied by 182 hydrants, 96 of which measure 4" and 86 of which measure 6". The tertiary network, the outlets, is 40,391 m long and will be made with PVC-O pipes of 100 to 200 in diameter of 16 atm. The tertiary network moves the flow of 53,462.32 m3. A total of 233 outlets have been designed for the tertiary network, depending on the supplied area and the size of each hydrant.

In each of the districts, a reservoir is planned at the beginning and end of this pipeline with a 99,859.47 m3 and 99,813.16 m3 capacity respectively. The first reservoir will be connected to a 1,000 mm diameter SRCP pipe and the second with an 800 mm diameter PVC-O pipe.

The excavation volume of the reservoirs is as follows: 58,833.22 m3 in the top reservoir and 36,817.24 m3 in the embankment. In the end reservoir, 97,552.95 m3 of clearing and 29,028.11 m3 of the embankment.

The reservoirs will have a bottom outlet and a drainage system that will connect to the valve station where the system can be controlled. The outlet will be made of helicoidal steel with an 813 mm external diameter and be 8 mm thick. The drainage will be made through a 508 mm external diameter and 6 mm thick helicoidal steel pipe, helically welded, shot-blasted, coated internally with epoxy paint and externally with epoxy paint or the equivalent, with a 200-micron minimum thickness, embedded in a reinforced beam with Ø 12 mm rods and HA-25 concrete, measuring 2.15 x 1.40 m.

The beam length is 39 m in the top reservoir and 37 m in the end reservoir. It starts at the valve station and ends at a 2.15 x 2.15 m concrete cube, which houses the bends of the intake pipe, and gives access to the discharge basin, from which the drainage pipe exits. On top of the basin, a properly protected waterproofing cover will be placed. The inlets will be made with a piece of boiler work, in the form of a grate.

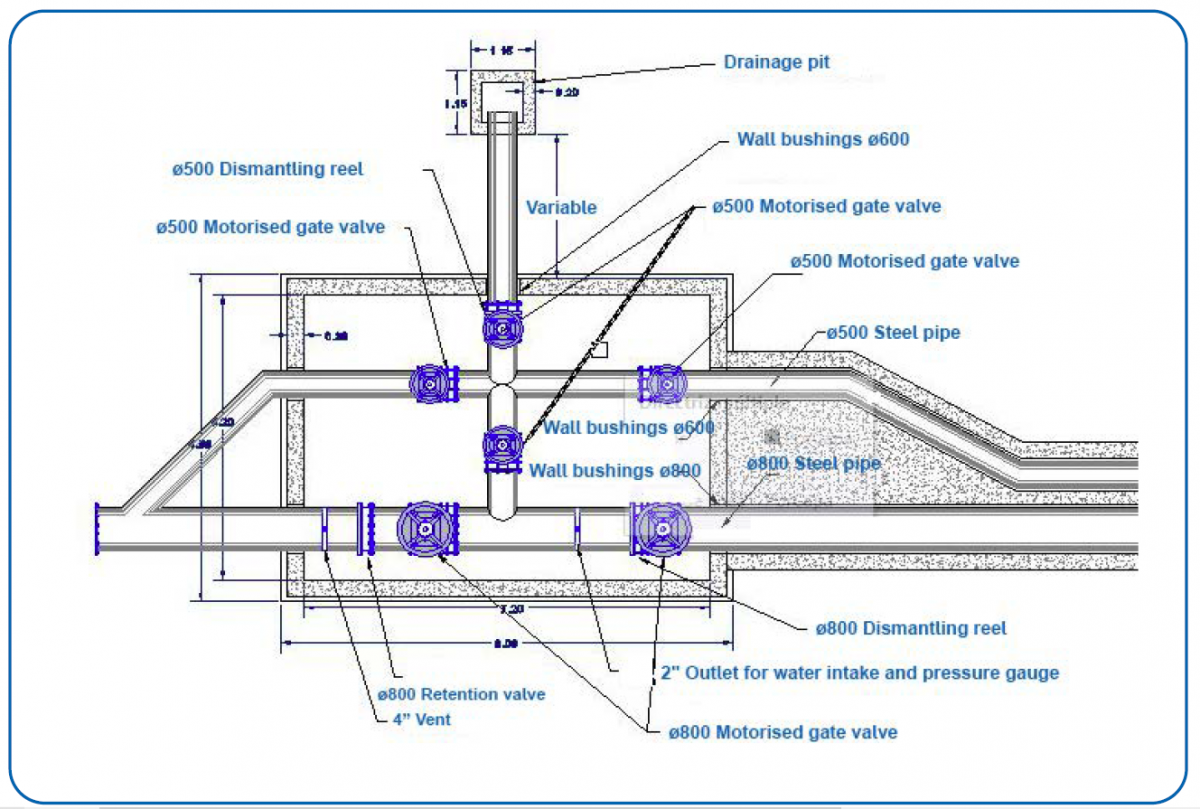

The tanks will be waterproofed by means of a 2 mm thick high-density polyethylene sheet, supported by a 250 gr/m2 perforated geotextile. A galvanized steel collector will be installed inside each station by means of the appropriate boiler workpiece, according to the reservoirs’ detailed plans, in which, from the filling pipe, the parallel installed drainage pipe will be connected through a bypass. Two sets of 800 mm diameter motorized valves will be fitted for the filling collector to facilitate opening and two sets of 500 mm diameter motorized valves for the drainage collector, as well as a gate valve with a 500 mm diameter reducer for the bypass and another for the drainage.

A 4" vent will be installed on the filling collector. Two 500 mm dismantling reels will be placed at the junction with the upstream valves, which will connect with the steel pipe flange joint that carries the water through the reinforced beam and from which a 3" pipe will be drawn to act as a balance chimney at the crest of the reservoir.

Both designed reservoirs fall outside the scope of the holder's obligations established in TITLE VII, on dam, reservoir, and basin safety, from the Regulations on the Public Hydraulic Domain. The first, the Arenillas de San Pelayo reservoir, has a 99,859.47 m3 storage capacity at its normal maximum level, with a 4.25 m foundation height, and the second, the Villanuño de Valdavia reservoir, has a 99,859.47 m3 storage capacity at its normal maximum level, with a 4.98 m foundation height. The Dam, on the other hand, has a 12,449.32 m3 holding capacity and a 3.20-meter foundation height.

The high hydraulic capacity and smooth surface make Class 500 PVC-O the ideal material for transporting water with minimum energy consumption. This circumstance, together with the current power situation, in which the electricity contracted throughout the year is a burden for many Irrigation Communities that only use it for 6 months a year, makes the designers consider PVC-O as another tool for optimizing the electricity costs in a modernization or irrigation transformation project.

The transformation of the irrigable area of the “ Vegas del Bajo Valdavia (Palencia) Irrigation Community” into an irrigation area is an example of optimal design, doing away with the need for electricity to distribute the irrigation water, taking advantage of the area's natural slopes, so that all the parcels in the area can enjoy water under suitable pressurized irrigation conditions.

These qualities would be of no use if the material's durability jeopardized the large investments that are being made. Therefore, we can talk about energy efficiency in water transport along with other qualities that are no less important, such as the material's durability, its low speed, and its high impact resistance.

Until this highly complicated power situation changes, the viability of these modernization initiatives depends on taking into account, during the design phase, as many measures as possible to reduce the operation's dependence on electricity costs, high accumulation basins, remote control systems that allow irrigation to be grouped together, frequency variations in the drives, adapting the pumping equipment to different possible demands and, of course, the use of materials in the irrigation network whose properties, as in the case of PVC-O, allow this energy optimization goal to be achieved.