In opposition to other existing systems, Molecor Technology produces the socket at the same time as the rest of the pipe to achieve the optimum conditions for Molecular Orientation. In addition to the process simultaneity and stability, Molecor’s patented technology allows for different degrees of orientation in the required sections of the socket and for specific wall thickness distribution.

The socket’s design in PVC-O pipes does not only depend on certain geometry criteria or thickness distribution. Sockets are expected to maintain the excellent properties attained during Molecular Orientation.

For that reason it is important to attain the right orientation degree on each part of the socket, since it is known how stresses are different along the different sections of the socket.

The socket is the most important part of the pipe. Socket geometry is complexer than in the rest of the pipe, and stresses are higher, mainly in the axial direction. Moreover, its extra dimension compared to the barrel makes it more exposed to impacts, scratches and other damages during installation.

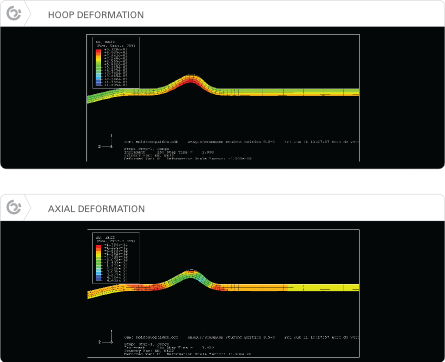

FEM simulation of a PVC-O pipe behaviour with axial and hoop orientation.