It is necessary to distinguish between the hydraulic pressures exerted on the pipeline or the network and the pressures each component is capable of withstanding individually.

Hydraulic pressures exerted on the pipe network

- Static pressure. This is the pressure in a section of pipe, when loaded, the water is at rest.

- Design pressure (DP). Maximum operating pressure under a permanent system of the network or pressure zone in a pipe section, excluding the water hammer. It should be noted that:

Pumping system pipe: Operating pressure = Design pressure > Static pressure.

Gravity pipe: Operating pressure < Static pressure = Design pressure.

- Maximum design pressure (MDP). Maximum operating pressure under a permanent system of the network or pressure zone that can be achieved in a section of pipe in service, considering fluctuations caused by a possible water hammer. This maximum design pressure is for which the pipe is actually designed:

- MDP is designated MDPa when the allowed water hammer is previously set.

- MDP is designated MDPc, when the water hammer is calculated.

- Network test pressure (STP). Hydrostatic pressure applied to a newly installed pipe to ensure its integrity and tightness.

- Working pressure (WP). Internal pressure that appears at a given time on a given point of the water supply network.

- Service pressure (SP). Internal pressure at the point of connection to the consumer installation, with zero flow in the mains.

Pressures on the components

- Nominal pressure (PN). Numerical value of a conventional series adopted, for reference purposes, to characterize the pipes, special parts and other elements of the pipe relative to the inner hydraulic pressure (kp/cm2) that can be withstood in the absence of external loads. Like the DN, the geometric characteristics of the coupling elements (flanges and others) of the same series of PN will be such that they enable the connection between them.The ratio between the values of the PN and inner hydraulic pressure depends on:

- Type of material.

- Temperature.

- Conception of the element in question (use in the short or long term).

- Safety coefficient applied.

In short, it can be said that the PN is the pressure the element is capable of withstanding in service without considering the water hammer (design pressure, DP) and in the absence of external loads.

The ISO 16422 standard (see Appendix "Standards and Certifications") "Pipes and couplings made of oriented unplasticized poly(vinyl chloride) (PVC-O) for the conveyance of water under pressure. Specifications "defines four possible nominal pressures for PVC-O class 500 and design coefficient 1.4:

PN: 12.5, 16, 20, and 25 (kp/cm2)

- Allowable Operating Pressure (AOP). Maximum hydrostatic pressure a component is capable of withstanding permanently in service.

- Allowable test pressure (ATP). Maximum hydrostatic pressure a newly installed component on site is capable of withstanding for a relatively short period of time, to ensure pipe integrity and tightness.

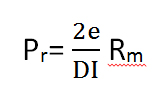

- Burst pressure (BP). Inner hydrostatic pressure which, in the absence of external loads, renders the pipe material out of service. In pipes of homogeneous material, this pressure is related to the minimum tensile strength (Rm) of the material, using the expression:

Pr: burst pressure, in N/mm2

e: thickness of the pipe wall, in mm

ID: inner diameter, in mm

Rm: minimum tensile strength of the material, in kp/cm2

In TOM® PVC-O pipes, it corresponds approximately to the concept of LCL (tension withstood by the material at 20 ⁰C and 50 years with a reliability level of no less than 97.5%).